Inspection and Data Recording System is a digital-based software designed to collect, store, manage, and analyze data generated during the inspection and testing process of industrial equipment. This system is used to monitor and document the condition of equipment or systems in industrial facilities. By using this system, companies can ensure that the equipment and facilities used are in optimal condition and in accordance with applicable safety standards and regulations.

.jpeg)

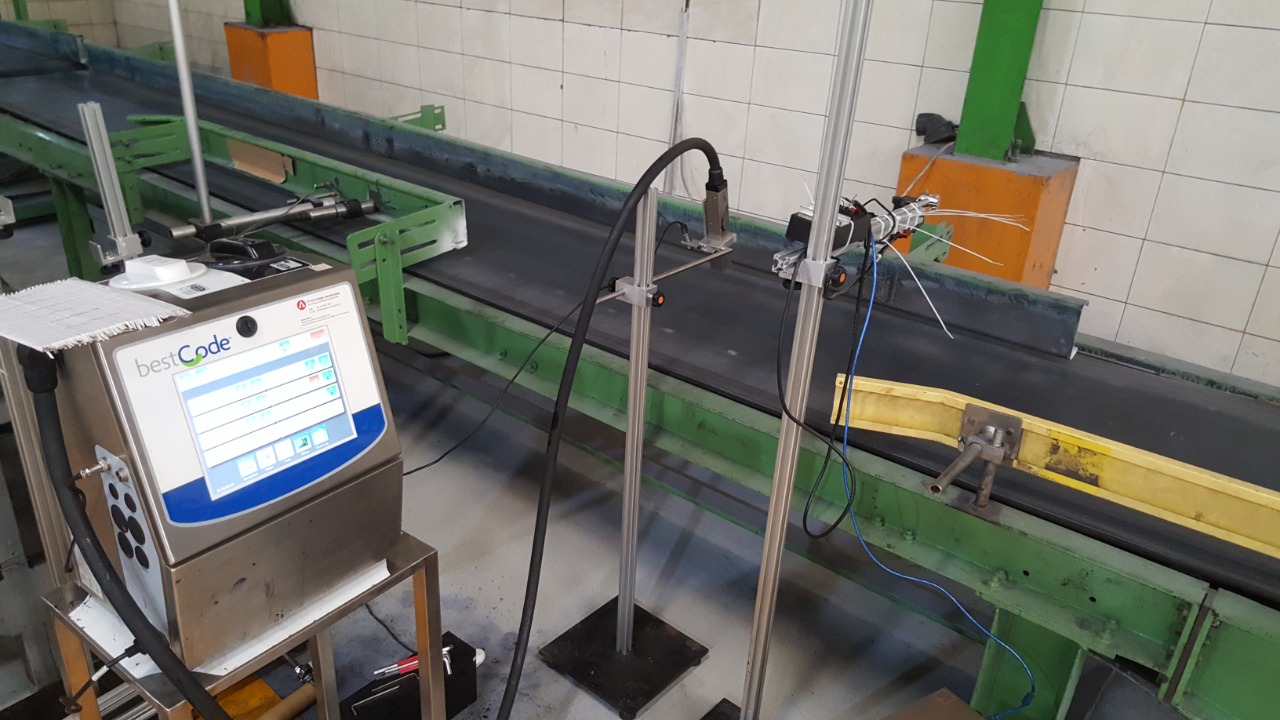

Inspection Vision Camera System is a technology that uses sophisticated cameras and software to perform automated visual inspections of objects or products. The system can detect defects, measure dimensions, recognize characters or codes, and verify the presence or position of components on the product.

Serialization Management is the process of managing and tracking the unique serial code assigned to each unit of product or packaging in the supply chain. The main objective of Serialization Management is to identify and track each product individually from the production stage to the end consumer. This helps prevent product counterfeiting, enhances safety, and ensures regulatory compliance.

OCR-Based Inspection System provides a timely and efficient solution with advanced optical character recognition capabilities. Ensuring product quality is maintained and inspection processes are running smoothly.

Our Vision Inspection System provides precise and in-depth monitoring to identify defects with high accuracy. Improve product quality and production efficiency.

Our inspection system is capable of reliably detecting object patterns and presence, providing high-quality supervision to ensure production consistency and accuracy.