PLC is an electronic hardware that can be programmed to automatically regulate and control various processes in the industrial world. Basically, PLC functions as the "brain" of an automatic control system, processing data received through input, and producing output that will control machines or other equipment in the industrial process.

In other words, PLC is an industrial computer optimized to control and monitor industrial processes that require real-time control and durability in harsh environments. PLCs are commonly used in factories, industrial machinery, and various other automation applications.

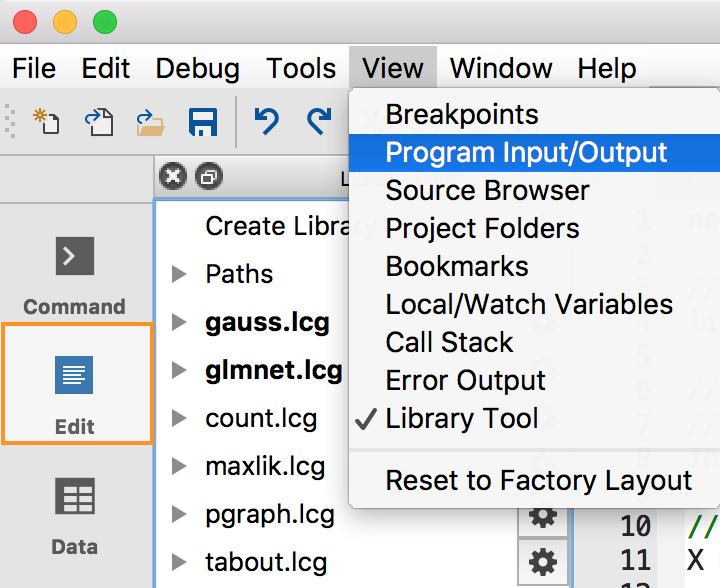

We provide automation solutions tailored to your company's specific needs. We bring the latest technological innovations to design and develop efficient, intelligent and safe PLC programs.

If you need help editing or enhancing an existing program, our team will provide the right solution for your needs. With our experience and expertise in PLC programming, we are ready to ensure that your program runs optimally and efficiently.

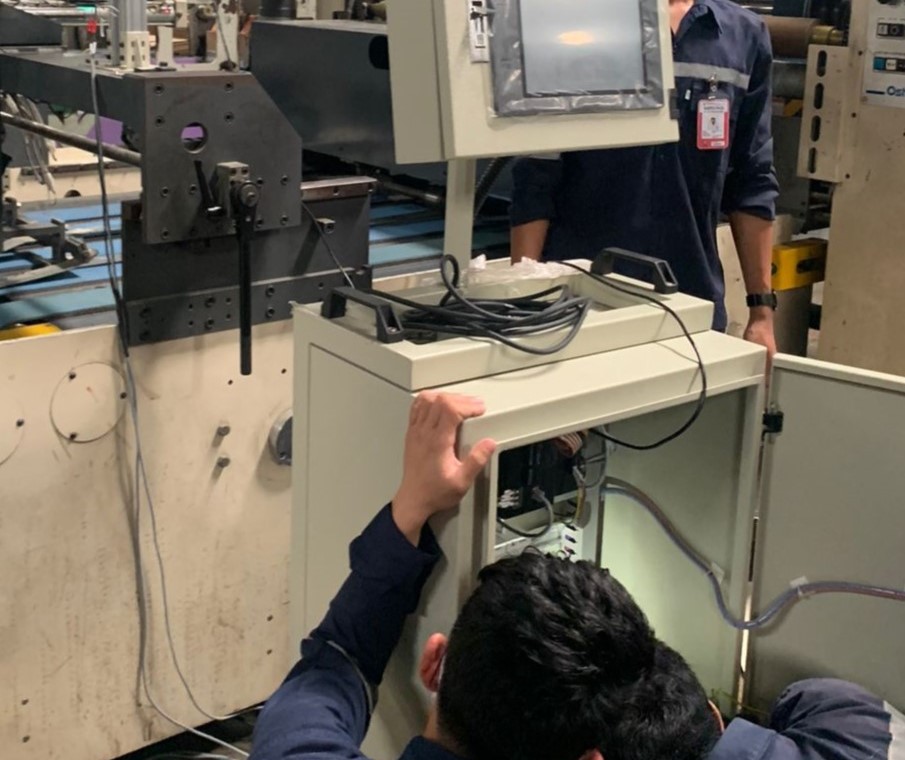

We are a reliable PLC troubleshooting service provider to solve problems in industrial automation systems. With a team of experienced experts, we are ready to identify and fix operational disruptions quickly and efficiently. We focus on customer satisfaction with timely solutions, reducing production downtime and increasing productivity.

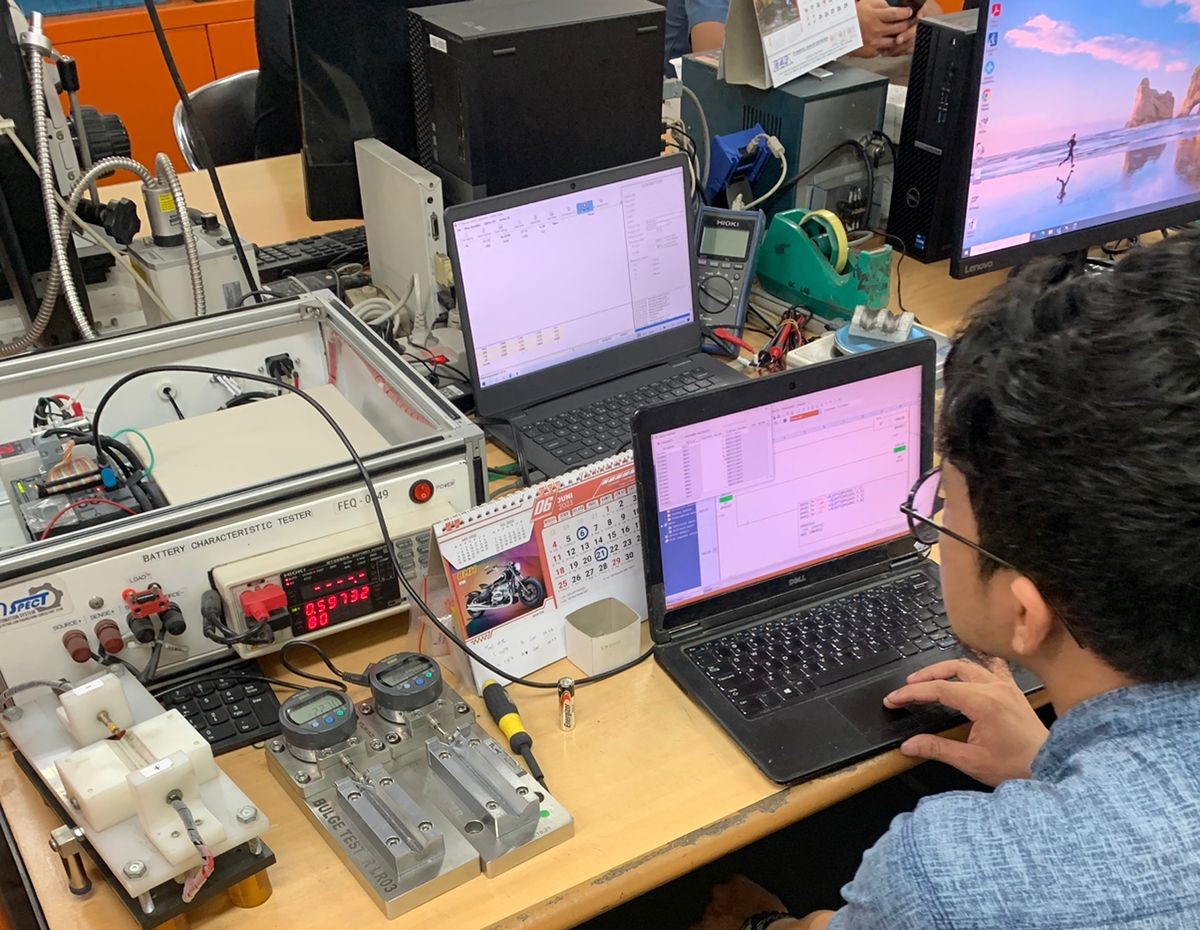

Project for adding "Moving" servo to the Packaging aging machine, there is a barcode scanner that can move 3-Axis reading, there is a development request for additional movement from the servo so that it can move to the fourth position.

We have developed a sophisticated digitalization management system to monitor products efficiently. By embedding a unique QR Code on each product. We use scanners to collect important data such as Production date, Production line, Batch number, and others.

Imagine a situation where product filling using a forward nozzle resulted in an unrecoverable product filling, which caused 36 days of downtime. In just two days, we were able to provide a solution to overcome this challenge. Want to know how our rapid transformation was done?